Today, data centre operators have two dominant battery chemistry choices for their UPS backup systems; Valve Regulated Lead Acid (VRLA) or lithium-ion (Li-ion). Of the two, the longer-established VRLA persists as the most popular and is forecast to remain so for the foreseeable future. It is environmentally friendly, being 98% recyclable, and sealed VRLA units are safe to use, without requiring maintenance.

However, steady advances in Li-ion’s technology are increasing its penetration of the North American and Europe data centre markets. And for some applications, which can particularly benefit from its specific features, it has become the favourite. It offers an optimum solution, for example, where reliable power must be delivered from a compact, lightweight battery implementation. This demand can arise in not only data centres, but also other critical applications such as healthcare, building infrastructures, manufacturing, and transportation.

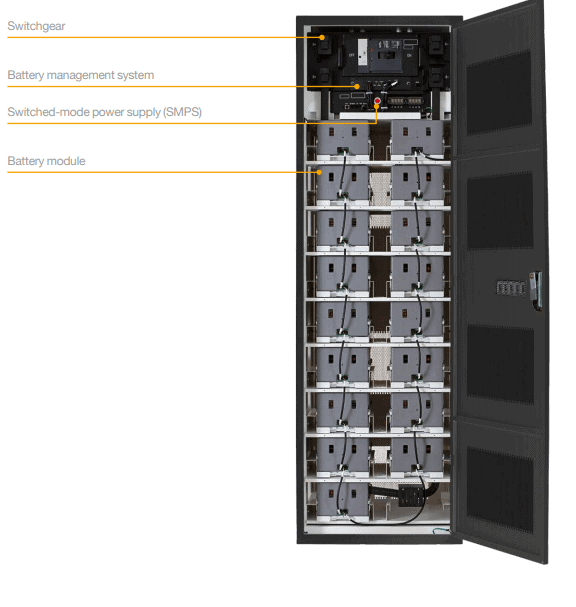

The KOHLER Uninterruptible Power battery cabinet

KUP’s response to these situations is to offer a high energy density pre-packaged Li-ion solution, assembled into standard 19” racking within a tough outer enclosure, as shown in Fig.1.

Fig.1: Li-ion Battery cabinet, showing key components

This single cabinet, rated at 34.6kWh, comprises one switchgear, one dedicated 24 V switched mode power supply (SMPS), and 17 battery modules, with fuse and moulded case circuit breaker protection. It also includes dedicated battery management systems (BMSs) at single module and rack level. Multiple cabinets can be paralleled to a maximum capacity of 5 MW.

The switchgear collects information about each battery cell, controls all battery module management systems, and calculates state of charge (SoC) and state of health (SoH). It also contains the circuit breaker and a shunt resistor. The SMPS supplies the power for the BMS and communicates with the UPS and other paralleled battery racks. It is available in two versions; with or without BMS for single or multiple parallel configuration.

Each of the 17 battery modules contain eight series-connected 67 Ah, 3.8 V cells and a dedicated battery module management system.

Lithium-ion advantages

As mentioned, the cabinets’ primary features include high energy density and light weight. For example, a VRLA configuration supporting a 190kW load with a 10 minute autonomy would weigh 2500 kg, with a volume of 2 m3. The same configuration, if implemented with Li-ion batteries, would weigh 550 kg and occupy 0.8 m3. Installation is easier, less data centre real estate is consumed, and civil engineering overheads are reduced.

Li-ion life is projected at 10-12 years , compared to 7 – 8 years for VRLA.

Li-ion charge and discharge performance can be superior. In our example, VRLA could charge at 0.1C, and discharge at 2C, while Li-ion could charge at 0.5C, and discharge at 6C. Firstly, this means that Li-ion could charge five times faster than VRLA (If the charger is capable); this reduced recovery time is an advantage in the event of multiple power failures. Secondly, Li-ion provides higher power density and efficiency, especially under heavy discharge rates. This eliminates the need for battery oversizing.

Cooling costs can be significantly reduced, as Li-ion batteries are tolerant to environmental temperature changes and can operate over a broad temperature range. By contrast, VRLA battery rooms must be kept at a reasonably constant temperature of around 20 °C; this can be problematic and costly, in hot countries the temperature is kept at higher temperatures and it is expected that the battery will age earlier. Both Li-ion and VRLA will age prematurely in high temperatures.

Conclusion

While Li-ion prices have been falling, their capital cost is still higher than that of VRLA batteries. They can increasingly be expected to take their place as a viable alternative to VRLA, with choice dictated by individual user circumstances and preferences. The decision is made easier with the availability of ready-packaged solutions like the Li-ion battery cabinet from KUP.