If asked to name our UPS’s most vital attribute, we may be tempted to say ‘reliability’. However, while reliability is indeed essential, it’s not the ultimate goal. What really counts is availability, as this measures how much time per year a system is operational and performing as it should. To understand these concepts better, we can look more closely at availability, and then see how it benefits from reliability.

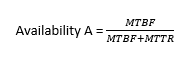

Availability has a more formal definition, which is:

Where:

A = Availability

MTBF = Mean Time Between Failures

MTTR = Mean Time To Repair

From this, we can see that we can improve availability both by increasing MTBF, and by decreasing MTTR. MTBF is the average number of hours until the power protection system fails. It is derived using calculations of all the UPS component MTBFs, based on a recognised standard such as MIL-HDBK-217F. A single high quality UPS assembly will have MTBF figures of around 125,000 hours.

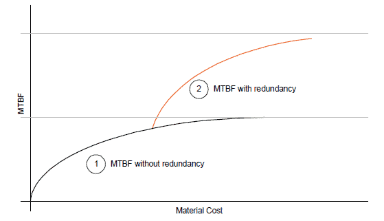

The MTBF of the system can be increased either by improving the reliability of every component in the system, or by ensuring that the system remains available even during the failure of an individual component. Yet there’s a finite limit to how reliable individual components can get, even with increased cost. Figure 1 shows how investing in higher component quality soon brings diminishing returns.[/vc_column_text][vc_single_image image=”14985″ img_size=”full” add_caption=”yes” alignment=”center” onclick=”img_link_large”][vc_column_text]However, the figure also shows an alternative way of improving MTBF; adding another UPS assembly to provide a level of redundancy. Doing so with the single module described above will create a 1+1 redundant system with an MTBF increased to 1,250,000 hours.

Remember, though, that availability depends on reducing MTTR as well as increasing MTBF. One highly effective way of achieving this is to build UPS systems as a set of self-contained, independent UPS modules. If a modules fails, it can swiftly be removed and replaced with a good unit, in an operation that can typically be completed within half an hour. By contrast, a monolithic system that must be repaired in situ will more usually need about six hours to complete repairs and bring the UPS back on line.

Note that MTTR only measures the time taken by a technician working on the UPS and repairing the fault. However, it’s also essential to minimise or eliminate the time that elapses between the fault occurring and the technician arriving at the UPS. This can only be achieved by a fully-resourced service organisation that’s equipped to provide this time-critical response. KOHLER Uninterruptible Power, for example, offer a 24/365 guaranteed response time, coupled with a ‘first visit repair’ approach. This means that the attending technician will be correctly trained, with the right documentation, diagnostic and repair tools, and modules or monolithic system components of the correct type and revision level – everything they need, in fact, to complete the repair immediately during the visit.

By contrast, some organisations’ first visit will only be diagnostic. They won’t be able to complete the repair until a second visit, after they have obtained the replacement parts indicated by their diagnosis.

Overall, while we can see that while reliability does play an important role in UPS availability, there are also other essential factors. Adding a level of redundancy enormously boosts availability; if sufficient steps to reduce MTTR through using modular design, and time to site, facilitated by an excellent service provider, are also taken, 99.9999 percent, or ‘six nines’ availability becomes possible for the UPS system.

KOHLER Uninterruptible Power is able to advise both on the hardware and the service support necessary to achieve this level of availability.