The primary function of any UPS system is to provide a reliable source of power in the event of a catastrophic loss of mains electricity. Typically, above a certain level the UPS will also operate in conjunction with a standby diesel generator, which once operational will take over from the UPS and maintain the power supply until the mains power is restored.

The justification behind this type of investment is fairly simple – the cost incurred from a loss of power and the resulting business interruption is significantly greater than the cost of the system put in place to guard against it. This is undoubtedly true of any transaction/process related business or data centre. For major financial and investment institutions, where millions of pounds of transactions could be taking place every second, UPS systems are especially vital.

As one of the largest banks in the in the world, the Royal Bank of Scotland (RBS), operates as a cornerstone of the UK economy. Its success is dependent on highly resilient business infrastructure systems and services. UPS’s are therefore a vital and fundamental component of this. As a result, RBS has adopted an uncompromising approach when it comes to specifying a UPS. At the core of its policy is the need to maintain high availability. However, of equal importance is the need to reduce ongoing costs, increase energy efficiency and provide the flexibility to support the growth of its business infrastructure and services.

Earlier this year RBS identified a requirement for a new, highly resilient UPS system to support trading operations within a key central London office. The area in question represents a key revenue centre for RBS in the capital, and as such required the highest levels of power protection to ensure against any eventuality. Phil Jones, Area Property & Technical Operations Manager for RBS, explains the requirement:

“As a business we regularly review all aspects of our mechanical, electrical and IT infrastructure to ensure it is meeting our needs and to understand where efficiencies can be made. As part of this process, we concluded a new UPS system was required to maintain the desired level of protection provided to this particular floor. Representing one of main trading floors within our portfolio, a loss of mains power combined with a system fault would have disastrous consequences on the business’ reputation – as well as significant financial implications. Because of this, we wanted to install additional redundancy within the system supporting this area of the business. The existing UPS was offering an acceptable level of protection but we wanted to maintain true 2N resilience and that was not achievable with the system currently being used. For us, it was all about identifying potential risk and eliminating it.”

Phil Jones, Area Property & Technical Operations Manager, RBS

“KUP’s team presented its latest product development to us, the PW 9500DPA, and thankfully it answered all of our needs. Its ability to support a load of 400kVA within a single frame, whilst still offering N+1 redundancy was a big advantage over competitors’ products.”

With any high value building, finding available space for additional infrastructure is always challenging and this project was no exception. The limited space RBS did have was within an existing generator tank room and came from being able to reduce the size of the fuel tank itself. The business therefore required a UPS which offered an extremely high power density within a small physical footprint, without compromising the required protection for the size of the load.

“KUP is an existing supplier to RBS and I had first-hand experience of the quality of the products and service it offers so it was the obvious choice with which to discuss our requirements and identify a possible solution. KUP’s team presented its latest product development to us, the PW 9500DPA, and thankfully it answered all of our needs. Its ability to support a load of 400kVA within a single frame, whilst still offering N+1 redundancy was a big advantage over competitors’ products. The product’s small footprint also meant we had the room to install two separate units side by side to provide the 2N system redundancy we wanted,” added Phil.

UK Operations Director for KUP, Alex Emms, picks up the story and explains some of the reasons which made the PW 9500DPA the ideal choice: “The PW 9500DPA has been designed with efficiency and flexibility at its core. As Phil mentioned, power density was a key factor and with a footprint of just 1.49m2, the PW 9500DPA delivers a class leading power density ratio of 335kW/m2. It is a truly modular product that can be scaled vertically in 100kW steps to provide up to 500kW of power in a single frame, or, 400 KW in a N+1 redundant configuration. This represents the largest capacity within a single frame available from any supplier and presents a number of benefits in terms of redundancy and hot swappability. The PW 9500DPA can also operate with six frames in parallel to provide horizontal scalability up to 3MW.

“The PW 9500DPA also answered RBS’ policy for only installing the most energy efficient products. The UPS has ‘true online’ efficiency of up to 96.1%, and that can be boosted to greater than 99% if you are able to run the system in eco-mode, helping RBS’ to meet its own targets for carbon reduction, as well as reduce ongoing running costs.”

The advanced decentralised parallel architecture (DPA) offered by the PW 9500DPA means each that module contains all the hardware and software required for full system operation, which in turn helps produce extremely high availability (six nines). Modules can be safely replaced whilst the system is still online, without risk to the critical load, reducing mean time to repair.

“When it came to the installation, the KUP team were again excellent and most importantly, there was zero impact on the business.”

Phil Jones, Area Property & Technical Operations Manager, RBS

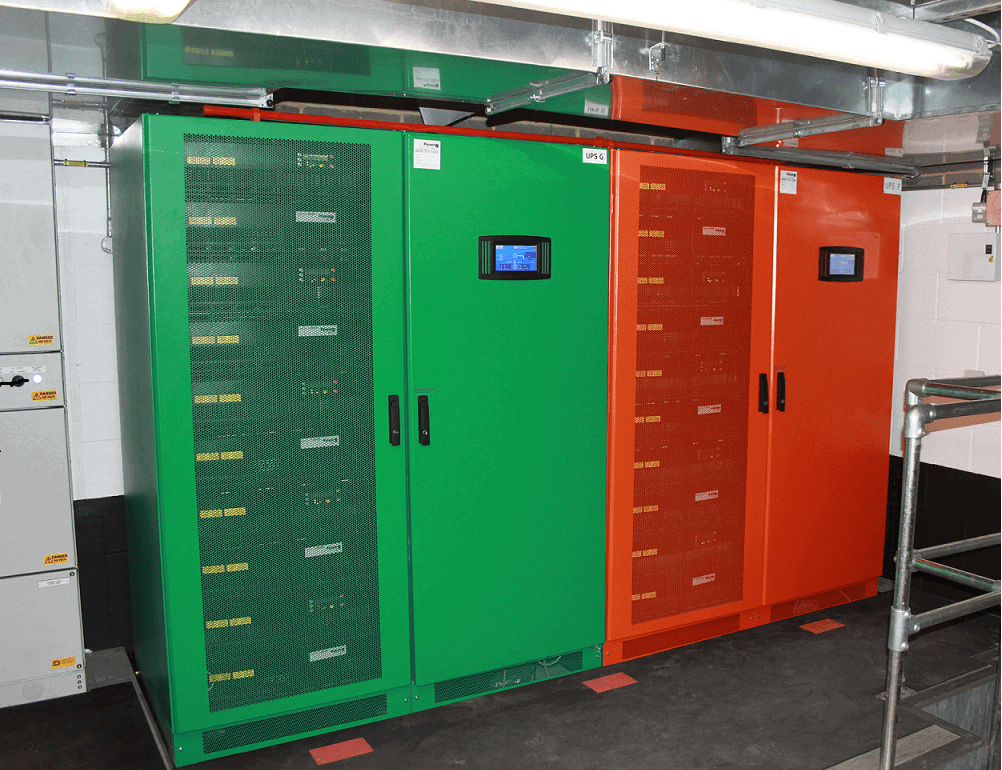

Following the decision on the selected product and required capacity, RBS’ electrical engineers, Arthur McKay, were called in to work with KUP to design the UPS integration requirements. The team then travelled to the banks of Lake Maggiore in Southern Switzerland to KUP’s design and manufacturing facility, to perform comprehensive factory acceptance testing (FAT) of the PW 9500. It was at this stage that RBS asked if it was possible to colour code the two UPSs to make it easier for engineers to identify which power source was currently active:

The fundamental motivation for this project was to create a true 2N+1 redundant system, where all the equipment runs separately with no single points of failure and any power outages would have no adverse effect on availability. With two identical UPS units sitting side by side, we wanted a way to provide an additional visual identifier relating to the two power streams. Having one UPS in green and the other in red seemed like a really helpful idea. The KUP team were enthusiastic about finding a way to make it happen and the result is exactly what we wanted.

“When it came to the installation, the KUP team were again excellent and most importantly, there was zero impact on the business. We performed one day of on site testing on a Saturday, meaning there was no interruption to our trading activities. Overall we have been extremely impressed with the professionalism of everyone involved in the project, from the initial enquiry to pitting the system online, KUP have been on hand every step of the way, ” added Phil.

Follow us on LinkedIn for regular industry articles & company information